The battery enclosure is a central element of a battery-electric car. Welding its varied elements presents particular challenges for the welding know-how used. Scansonic now provides the ALO4 sequence of laser welding optics, offering appropriate options for every of those duties. Mixed with out there laser beam sources and a wire feeder, a complete system for laser beam welding on this essential utility space is now out there.

Regardless that the automotive trade is presently present process structural adjustments, it’s sure that the way forward for passenger automobiles shall be battery-electric. The precise timeline for this transformation stays open, however all producers are already persistently aligning their mannequin ranges in the direction of electromobility. This shift has far-reaching implications for manufacturing: whereas conventional areas similar to engine and transmission manufacturing are dropping significance, new necessities are coming into focus. One of many central challenges is establishing appropriate manufacturing applied sciences for sequence manufacturing. The manufacturing of the battery enclosure is especially within the highlight, contemplating the basic parameters of business mass manufacturing: cycle time, high quality, and value.

Complicated Battery Enclosures

The lithium-ion batteries utilized in electrical automobiles are mechanically delicate and should be reliably protected in opposition to impacts, excessive temperatures, and moisture. Accordingly, excessive calls for are positioned on the battery enclosure: it should be sealed, have excessive rigidity, and embody buildings for cooling the cells. On the identical time, low weight and economical manufacturing prices are important. In most car ideas, the battery pack is built-in into the car flooring, reducing the middle of gravity and growing passive safety within the occasion of an accident.

In sequence manufacturing, most OEMs depend on battery enclosures manufactured from aluminum. The decrease weight in comparison with metal has a direct constructive impression on vary. Aluminum-magnesium-silicon alloys of the 6000 sequence are sometimes used, as they provide a superb weight-to-strength ratio. Nevertheless, a specific problem arises from their elevated tendency to kind scorching cracks – a facet that locations particular calls for on the welding course of.

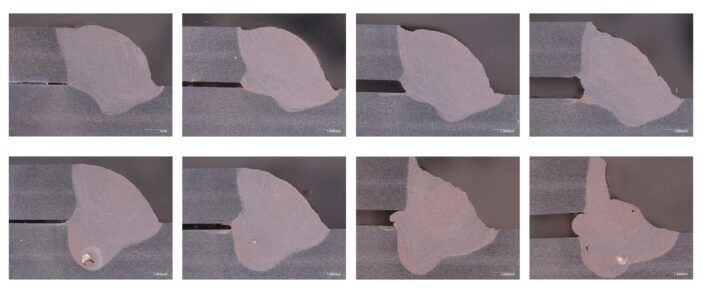

Along with the fabric, the geometry of the battery enclosure additionally locations excessive calls for: various kinds of weld seams similar to fillet welds, butt welds, and T-joints should be reproducibly joined with top quality. Overlap joints can have gaps because of manufacturing tolerances that should be reliably bridged in the course of the welding course of.

Challenges of Laser Welding

For the weld seams required within the battery enclosure, laser welding provides decisive benefits over typical strategies. It permits excessive processing speeds with exact vitality enter – relying on the applying, the welding pace may be about twice as excessive as arc welding. The low warmth enter additionally considerably reduces the chance of deformation of the element in the course of the becoming a member of course of.

Regardless of these benefits, many producers have to this point hesitated to make use of laser know-how persistently, as appropriate optics weren’t out there for all becoming a member of factors. A mixture of laser and arc welding throughout the identical manufacturing facility usually appears impractical for mass manufacturing.

Appropriate Laser Welding Optics for All Necessities

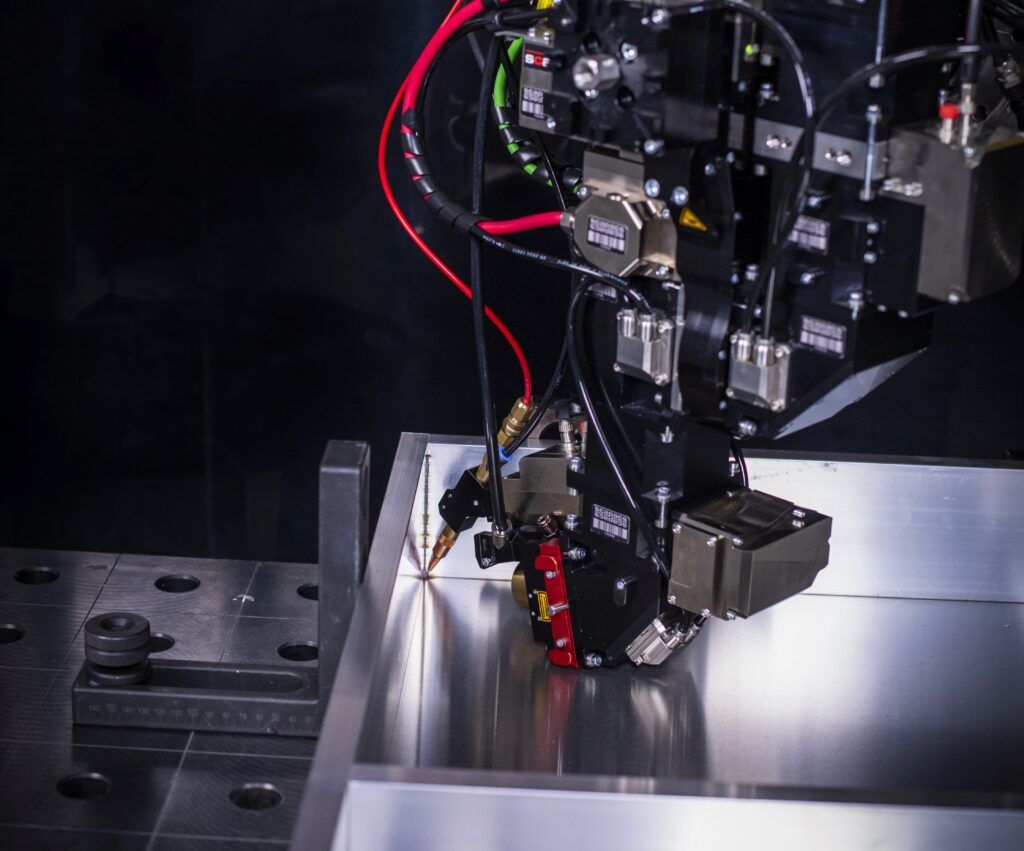

Scansonic, a number one producer of laser processing optics for 25 years, has particularly developed its established ALO4 to satisfy the necessities within the battery enclosure sector. The ensuing household of processing optics now covers all welding duties on this space. An extra wire is used within the course of. This not solely reinforces the seam but in addition ensures, with the so-called tactile seam monitoring, that the processing at all times takes place precisely on the fringe of the element.

Particularly for hot-crack-prone aluminum alloys of the 6000 sequence, the extra wire provides an efficient method to course of stabilization, notably concerning the formation of scorching cracks. Gaps as much as one-third of the thickness of the higher element may be reliably closed – the ensuing weld seams are steady and crack-free.

Even bigger tolerances may be bridged if the optic is moreover outfitted with beam oscillation. In growing the ALO4-O, the engineers utilized current know-how for each tactile and distant welding processes. The ALO4-O combines tactile seam monitoring with the laser beam oscillation of a distant optic. Two synchronized scanner axes allow oscillations of the laser beam as much as 1,000 Hz. Oscillation form, amplitude, and frequency are freely programmable. The method may be designed in order that materials from the higher element is melted and used along with the extra wire for hole filling – tolerances as much as 50 % of the fabric thickness may be compensated. The beam oscillation additionally provides vital benefits for processing thicker sheets, such because the battery enclosure lid, because it achieves a large seam reference to a smaller laser beam focus. This implies much less warmth enter in comparison with a bigger spot with out oscillation.

Changes for Geometrically Demanding Joints

Some weld seams should be made contained in the battery enclosure – with correspondingly restricted accessibility for the instrument. The ALO4-L laser welding optic was developed for these purposes. Its prolonged telescopic arm permits deeper penetration into the battery enclosure; the working distance is about 70 mm better than the opposite variants of the ALO4 household.

For vertical seams inside, the sequence was additionally expanded with the ALO4-F. This optic makes use of a 3rd deflection mirror that deflects the beam by 115°. This enables the vertical seams within the corners of the battery enclosure to be reliably reached and welded.

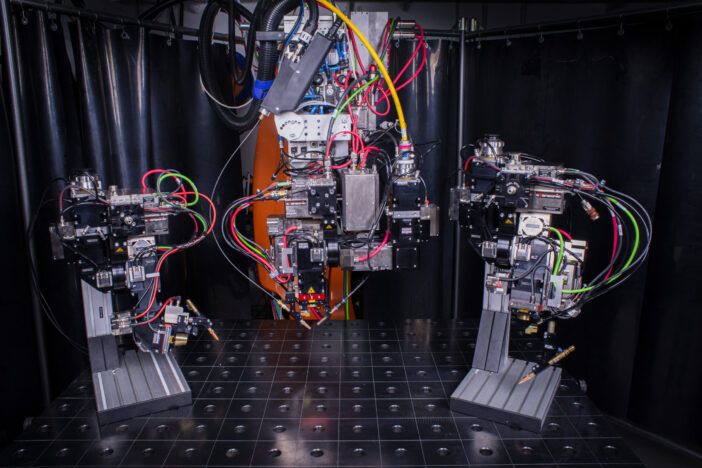

A Persistently Coordinated Full System

The coordinated use of the 4 ALO4 variants brings vital benefits for manufacturing. The frequent management system routinely acknowledges which ALO4 optic is linked and adjusts the parameters accordingly. Upkeep and spare elements stock are additionally simplified by systematic standardization.

The processing optics are appropriate with all frequent laser sources in the marketplace. For even simpler integration, Scansonic provides all different system elements together – together with the wire feeder from Dinse and appropriate laser sources from Brightlight Laser Methods – from a single supply. The result’s an optimally coordinated full system with excessive course of reliability.

All variants of the ALO4 sequence can be found with the SCeye course of monitoring system developed by Scansonic. This absolutely paperwork the welding course of. AI-based algorithms detect pores and spatter that escape from the soften pool. Moreover, all related machine and course of parameters are repeatedly monitored – an essential foundation for seamless high quality assurance in sequence manufacturing.